High Temperature Applications

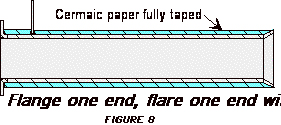

In applications where extremely elevated temperatures (1650 F) are present on the tube side of the exchanger care has to be taken not to warp the tube sheet. The use of tube inserts addresses this problem. Typically the tube insert has an hour glass form, creating an air gap between the tube insert and the parent tube. The gap is wrapped with high temperature (2300 F) ceramic paper. The paper is taped in place. We recommend taping the full length. There are two advantages for full length tape:

- Higher temperature ceramic paper can be compressed on to the tube insert

- The tape protects the ceramic paper which cannot withstand even minor abuse.

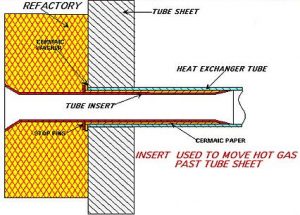

The tube insert extends out of the tube and that space is filled with castable refractory. Some tube inserts have anchors that become imbedded into the refractory; others have pins with ceramic paper washers to set the tube insert at a specific height from the tube sheet. The ceramic washer inhibits heat transfer from the tube insert to the tube sheet. Figure 8 represents a typical design with high temperature paper. Figure 9 represents how a high temperature tube insert is positioned within a unit.

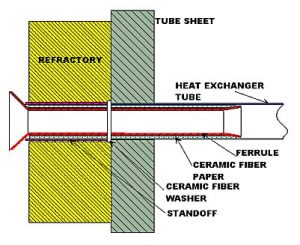

NS Industries has manufactured a unique ferrule assembly for use in high temperature applications. The ferrule assembly consists of four components:

- FERRULE

- CERAMIC FIBER PAPER

- CERAMIC FIBER WASHER

- STANDOFF TUBE

The ferrule is a metal tube insert formed to suit the application, and is completely wrapped with ceramic fiber paper of a suitable temperature rating, and completely taped. The taping is done under pressure, resulting in the compression of the ceramic fiber paper. A ceramic fiber washer is provided, sized to the application. The standoff tube is typically the same alloy as the ferrule and the same size as the heat exchanger tube. The components are assembled together as shown on the attached drawing.

Advantages

There are a number of advantages to this system:

- The ferrules can be removed, inspected, and if necessary, sent back to the factory for new ceramic fiber paper and taping, before returning to the unit.

- Only the ferrules that are worn out need to be replaced. This can be accomplished without the removal of the refractory.

- The design does not have any metal to metal contact from the ferrule to the tube sheet or the heat exchanger tube.

Figure 8

Figure 9